WRM1. River Training And Riverbank Protection Works

Instructional objectives:

1. The need for river training

2. Guide bunds for restricting the flow path of river waterway

3. Afflux bunds, approach embankments, groynes, spurs, etc. for river waterway control

4. The issue of riverbank failure and lateral migration of rivers

5. Different modes of bank failure

6. Techniques for bank stabilization

Introduction

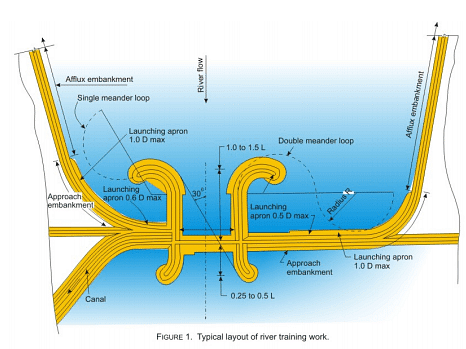

For constructing a hydraulic structure across a river, a water resources engineer must also consider the effect of the structure on the hydraulics of the river and the best ways to train the river such that the structure performs satisfactorily and also there is no significant damage to the riverine environment. For example, if a barrage is located within a river, then its length may span from end to end of the river width or could be smaller, if the waterway is so calculated. In the latter case, that is, when the length of a barrage is smaller than the width of a river, then certain auxiliary structures in the form of embankments have to be constructed as shown in Figure 1, known as River Training Works. At times, people residing very close to the flood zones of a river may have to be protected from the river’s fury. This is done by providing embankments along the river sides to prevent the river water from spilling over to the inhabited areas.

In order to limit the movement of the bank of a meandering river, certain structures are constructed on the riverbank, which are called riverbank protection works. Sometimes, an embankment like structure, called a Groyne or a Spur, is constructed at right angles to the riverbank and projected into the river for attracting or deflecting the flow of the river towards or away from the riverbank.

This chapter discusses the layout and design of these River Training and Riverbank Protection Works, which can together be termed as aspects of River Engineering. Of course, river engineering includes much more, like dredging to keep the pathway of ships in a river navigable, or techniques of setting up jetties for ships to berth, but they are not discussed in this lesson.

1 Guide bunds or banks

Alluvial rivers in flood plains spread over a very large area during floods and it would be very costly to provide bridges or any other structure across the entire natural spread. It is necessary to narrow down and restrict its course to flow axially through the diversion structure. Guide bunds are provided for this purpose of guiding the river flow past the diversion structure without causing damage to it and its approaches. They are constructed on either or both on the upstream and downstream of the structure and on one or both the flanks as required.

Classification of Guide Bunds

Guide bunds can be classified according to their form in plan as (i) divergent, (ii) convergent, and (iii) parallel and according to their geometrical shape as straight and elliptical with circular or multi-radii curved head. These are shown in Figure 2.

In the case of divergent guide bunds, the approach embankment gets relatively less protection under worst possible embayment and hence divergent guide bunds require a longer length for the same degree of protection as would be provided by parallel guide bunds. They also induce oblique flow on to the diversion structure and give rise to tendency of shoal formation in the centre due to larger waterway between curved heads. However, in the case of oblique approaching flow, it becomes obligatory to provide divergent guide bunds to keep the flow active in the spans adjacent to them.

The convergent guide bunds have the disadvantage of excessive attack and heavy scour at the head and shoaling all along the shank rendering the end bays inactive.

Parallel guide bunds with suitable curved head have been found to give uniform flow from the head of guide bunds to the axis of the diversion structure.

In the case of elliptical guide bunds, due to gradual change in the curvature, the flow is found to hug the bunds all along their lengths whereas in the case of straight guide bunds, separation of flow is found to occur after the curved head, leading to obliquity of flow. Elliptical guide bunds have also been found to provide better control on development and extension of meander loop towards the approach embankment.

Length of Guide Bunds

The length of the guide bund on the upstream is generally kept as 1.0 to 1.5L where L is the width between the abutments of the diversion structure. In order to avoid heavy river action on the guide bunds, it is desirable to limit the obliquity of flow to the river axis not more than 300 as indicated in Figure 1. The length of the downstream guide bund is kept as 0.25L to 0.4L.

For wide alluvial belt, the length of guide bunds is decided from two important considerations, viz. the maximum obliquity of the current and the permissible limit to which the main channel of the river can be allowed to flow near the approach embankment in the event of the river developing excessive embayment behind the training works. The radius of the worst possible loop has to be ascertained from the data of the acute loops formed by the river during the past. Where river survey is not available, the radius of the worst loop can be determined by dividing the radius of the average loop worked out from the available surveys of the river by 2.5 for rivers having a maximum discharge up to 5000 cumecs and by 2.0 for a maximum discharge above 5000 cumecs.

Curved head and tail of Guide Bunds

The upstream curved head guides the flow smoothly and axially to the diversion structure keeping the end spans active. The radius of the curved head should be kept as small as possible consistent with the proper functioning of the guide bund. The downstream curved tail provides a smooth exit of flow from the structure.

From the hydraulic model tests conducted for a number of projects over the past years, it has been found that a radius of the curved head equal to 0.4 to 0.5 times the width of the diversion structure between the abutments usually provides satisfactory performance. The minimum and maximum values could be 150 m and 600 m respectively. However, the exact values are to be ascertained from model tests. The radius of the curved tail generally ranges from 0.3 to 0.5 times the radius of the curved head.

According to the river curvature, the angle of sweep of curved upstream head ranges from 1200 to 1450. The angle for the curved tail usually varies from 450 to 600.

In the case of elliptical guide bunds, the elliptical curve is provided upto the quadrant of the ellipse and is followed by multi-radii or single radius circular curve. In case of multi- radii curved head, the larger radius adjacent to the apex of the ellipse is generally kept as 0.3 to 0.5 times the radius of the curved head for straight guide bund with the angle of sweep varying from 450 to 600 and the smaller radius equivalent to 0.25 times the radius of curve head for straight guide bund with sweep angle of 300 to 400.

Design of guide bunds

After fixing up the layout of the guide bunds in accordance with the guidelines mentioned in the foregoing paragraphs, the details of the guide bund sections have to be worked out. The various dimensions worked out are top width, free board, side slopes, size of stone for pitching, thickness of pitching, filters and launching apron. The guide lines for the same are given below.

Top width of guide bund

At the formation level, the width of the shank of guide bunds is generally kept 6 to 9 m to permit carriage of material and vehicles for inspection. At the nose of the guide bunds, the width is increased suitably in a bulb shape to enable the vehicles to take turn and also for stacking reserve of stone to be dumped in places whenever the bunds are threatened by the flow.

Free board for Guide Bund

A free board of 1 to 1.5 m above the following mentioned two water levels has to be provided and the higher value adopted as the top level of the upstream guide bund:

(i) Highest flood level for 1 in 500 years flood

(ii) Affluxed water level in the rear portion of the guide bank calculated after adding velocity head to HFL corresponding to the design flood (1in 100 year frequency) at the upstream nose of the guide bank.

On the downstream side also, a free board of 1 to 1.5 m above the highest flood level for 1 in 500 years flood is to be adopted.

Side slopes of guide bund

The side slopes of guide bund have to be fixed from stability considerations of the bund which depend on the material of which the bund is made and also its height. Generally the side slopes of the guide bund vary from 2:1 to 3:1 (H:V).

Size of stone for pitching

The sloping surface of the guide bund on the water side has to withstand erosive action of flow. This is achieved by pitching the slope manually with stones. The size and weight of the stones can be approximately determined from the curves given in Figure

3. It is desirable to place the stones over filters so that fines do not escape through the interstices of the pitching. For average velocities up to 2 m/sec, burnt clay brick on edge can be used as pitching material. For an average velocity upto 3.5 m/sec, pitching of stone weighing from 40 to 70 kg (0.3 to 0.4 m in diameter) and for higher velocities, cement concrete blocks of depth equal to the thickness of pitching can be used. On the rear side, turfing of the slope is normally found to be adequate.

Thickness of Pitching

The thickness of pitching is to be kept equal to the size of the stone for pitching determined. However, it should not be less than 0.25m. wherever the velocities are high for which the size of stone is greater than 0.4 m, cement concrete blocks of thickness

0.4 to 0.5 or 0.6 m may be used.

Provision of filter

It is always desirable to provide an inverted (graded) filter below the pitching stones to avoid the finer bund materials getting out through the interstices. The thickness of the filter may be 20 to 30 cm. Filter has to satisfy the criteria with respect to the next lower size and with respect to the base material:

(i) For uniform grain size filter,

R D50 of filter material 5 to 10

50 of base material

(ii) For graded material of sub-rounded particles,

R D50 of filter material 12 to 58

50 of base material

R D15 of filter material 12 to 40

15 of base material

Launching apron

Just as launching apron is provided for the main structure both on the upstream and downstream it has to be provided for guide bunds also in the bed in continuation of the pitching. The different aspects to be looked into are the size of the stones, depth of scour, thickness, slope of launched apron, shape and size of launching apron.

The required size of stone for the apron can be obtained from the curves. In case of non-availability of required size of stones, cement concrete blocks or stone sausages, prepared with 4 mm GI wire in double knots and closely knit and securely tied, may be used.

The scour depths to be adopted in the calculations for the launching apron would be different along the length of the guide bund from upstream to downstream, as given in the following table. The value of R, that is the normal depth of scour below High Flood Level may be determined according to Lacey’s scour relations.

Location Maximum adopted scour depth to be

Upstream curved head of Guide bund 2.5 R

Straight reach of guide bund to nose of downstream Guide bund 1.5 R

While calculating the scour values, the discharge corresponding to 50 to 100 years frequency may be adopted. However, after construction and operation of the diversion structure, the portions of the guide bund coming under attack of the river flow should be carefully inspected and strengthened as and when necessary.

The thickness of apron of the guide bund should be about 25 to 50 percent more than that required for the pitching. While the slope of the launched apron for calculation of the quantity can be taken as 2:1 for loose boulders or stones, it may be taken as 1:5:1 for c.c blocks or stone sausages.

From the behaviour of the guide bunds of previously constructed diversion structures, it has been observed that shallow and wide aprons launch evenly if the scour takes place rapidly. If the scour is gradual, the effect of the width on the launching of apron is marginal. Generally a width of 1.5 R has been found to be satisfactory. For the shank or straight portions of the guide bunds, the thickness of the apron may be kept uniform at

1.5 T where T is the thickness of the stone pitching. To cover a wider area, for the curved head, the thickness is increased from 1.5 to 2.25 T with suitable transition over a

length of L1 equal to one fourth of the radius of the curved head and provided in the shank portion only. On the rear side of the curved head and nose of the guide bund, the apron should be turned and ended in a length equal to about one fourth of the respective radius.

6.1.2 Afflux bund

Afflux bunds extend from the abutments of guide bunds (usually) or approach bunds as the case may be. The upstream afflux bunds are connected to grounds with levels higher than the afflux highest flood level or existing flood embankments, if any. The downstream afflux bunds, if provided, are taken to such a length as would be necessary to protect the canal/approach bunds from the high floods.

Afflux bunds are provided on upstream and downstream to afford flood protection to low lying areas as a result of floods due to afflux created by the construction of bridge/structure and to check outflanking the structure.

Layout of afflux bund

The alignment of the afflux bund on the upstream usually follows the alluvial belt edge of the river if the edges are not far off. In case the edges are far off, it can be aligned in alluvial belt, but it has to be ensured that the marginal embankment is aligned away from the zone of high velocity flow. Since the rivers change their course, it is not necessary that a particular alignment safe for a particular flow condition may be safe for a changed river condition. Hence the alignment satisfactory and safe for a particular flow condition (constructed initially) has to be constantly reviewed after every flood and modified, if necessary.

Top width of afflux bund

Generally the top width of the afflux bund is kept as 6 to 9 m at formation level.

Free board for afflux bund

The top level of the afflux bund is fixed by providing free board of 1 to 1.5 m over the affluxed highest flood level for a flood of 1 in 500 years frequency.

Slope pitching and launching apron

Generally the afflux bunds are constructed away from the main channel of the river. Hence they are not usually subjected to strong river currents. In such cases, provision of slope pitching and launching apron are not considered necessary. However, it is desirable to provide a vegetal cover or turfing. In reaches where strong river currents are likely to attack the afflux bunds, the slopes may be pitched as for the guide bunds.

A typical layout and section of afflux bund are shown in Figure 4.

6.1.3 Approach embankment

Where the width of the river is very wide in an alluvial plain, the diversion structure is constructed with a restricted waterway for economy as well as better flow conditions. The un-bridged width of the river is blocked by means of embankments called Approach embankments or tie bunds.

Layout of approach embankment

In case of alluvial plains, the river forms either a single loop or a double loop depending upon the distance between the guide bunds and the alluvial belt edges. Hence the approach embankments on both the flanks should be aligned in line with the axis of the diversion structure up to a point beyond the range of worst anticipated loop. Sometimes the approach embankments may be only on one flank depending on the river configuration.

Top Width of approach embankments

The top width of the approach embankment is usually kept as 6 to 9m at formation level.

Free Board of approach embankment

Free board for approach embankment may be provided similar to that for guide bunds.

Side slopes of approach embankment

The side slopes of the approach embankment have to be fixed from stability considerations of the bund which depend on the material of which the bund is made and also its height. Generally the side slopes of the guide bund vary from 2:1 to 3:1 (H:V).

Size of stone for pitching

Velocities for 40 percent of the design discharge would be estimated and the size of stone for pitching would be determined as for guide bunds discussed in Section 6.1.1.

Thickness of pitching

The Guide lines for determining the thickness of pitching would be the same as for guide bunds in Section 6.1.1. The velocities would be estimated for 40 percent of the design discharge.

Provision of filter

Generally filters are not provided below the pitching stones in the case of approach embankments. However, if the section of embankment is heavy, filter may be provided as mentioned for guide bunds discussed in Section 6.1.1.

Launching apron

The provisions of size of stone, thickness of apron and slope of launched apron would be similar to those of guide bunds mentioned in above paragraphs. But the depth of scour for the approach embankment may be taken as 0.5 to 1.0 Dmax and beyond that the width may be increased to 1.0 Dmax with suitable transition in the former reach.

6.1.4 Groynes or Spurs

Groynes or spurs are constructed transverse to the river flow extending from the bank into the river. This form of river training works perform one or more functions such as training the river along the desired course to reduce the concentration of flow at the point of attack, creating a slack flow for silting up the area in the vicinity and protecting the bank by keeping the flow away from it.

Classification of Groynes or spurs

Groynes or spurs are classified according to (i) the method and materials of construction (ii) the height of spur with respect to water level (iii) function to be performed and (iv) special types which include the following:

These are

(i) Permeable or impermeable

(ii) Submerged or non-submerged

(iii) Attracting, deflecting repelling and sedimenting and

(iv) T-shaped (Denehey), hockey (or Burma) type, kinked type, etc.

The different types of spurs are shown in Figure 5.

Impermeable spurs do not permit appreciable flow through them whereas permeable ones permit restricted flow through them. Impermeable spurs may be constructed of a core of sand or sand and gravel or soil as available in the river bed and protected on the sides and top by a strong armour of stone pitching or concrete blocks. They are also constructed of balli crates packed with stone inside a wire screen or rubble masonry.

While the section has to be designed according to the materials used and the velocity of flow the head of the spur has to have special protection.

Permeable spurs usually consist of timber stakes or piles driven for depths slightly below the anticipated deepest scour and joined together to form a framework by other timber pieces and the space in between filled up with brush wood or branches of trees. The toe of the spur would be protected by a mattress of stones or other material. As the permeable spurs slow down the current, silt deposition is induced. These spurs, being temporary in nature, are susceptible to damage by floating debris. In bouldery or gravelly beds, the spurs would have to be put up by weighing down timber beams at the base by stones or concrete blocks and the other parts of the frame would then be tied to the beams at the base.

Layout of groynes or spurs

Groynes are much more effective when constructed in series as they create a pool of nearly still water between them which resists the current and gradually accumulates silt forming a permanent bank line in course of time. The repelling spurs are constructed with an inclination upstream which varies from 100 to 300 to the line normal to the bank. In the T-shaped groynes, a greater length of the cross groyne projects upstream and a smaller portion downstream of the main groyne.

Length of Groynes

The length of groynes depends upon the position of the original bank line and the designed normal line of the trained river channel. In easily erodible rivers, too long groynes are liable to damage and failure. Hence, it would be better to construct shorter ones in the beginning and extend them gradually as silting between them proceeds. Shorter and temporary spurs constructed between long ones are helpful in inducing silt deposition.

Spacing of Groynes

Each groyne can protect only a certain length and so the primary factor governing the spacing between adjacent groynes is their lengths. Generally, a spacing of 2 to 2.5 times the length of groynes at convex banks and equal to the length at concave banks is adopted. Attempts to economise in cost by adopting wider spacings with a view to insert intermediate groynes at a later date may not give the desired results as the training of river would not be satisfactory and maintenance may pose problems and extra expenditure. T-shaped groynes are generally placed 800 m apart with the T-heads on a regular curved or straight line.

Design of groynes or spurs

The design of groynes or spurs include the fixation of top width, free board, side slopes, size of stone for pitching, thickness of pitching, filter and launching apron.

Top width of spur

The top width of the spur is kept as 3 to 6 m at formation level.

Free board

The top level of the spur is to be worked out by giving a free board of 1 to 1.5 m above the highest flood level for 1 in 500 year flood or the anticipated highest flood level upstream of the spur, whichever is more.

Side slopes

The slopes of the upstream shank and nose is generally kept not steeper than 2:1 the downstream slope varies from 1.5 : 1 to 2:1.

Size of stone for pitching

The guide lines for determining the size of stone for pitching for guide bunds hold good for spurs also.

Thickness of pitching

The thickness of pitching for spurs may be determined from the formula T = 0.06 Q1/3 where Q is the design discharge in cumecs. The thickness of stone need not be provided the same through-out the entire length of the spur. It can be progressively reduced from the nose.

Provision of filters

Provision of filter satisfying the filter criteria has to be made below the pitching at nose and on the upstream face for a length of 30 to 4 m for the next 30 to 45m from the nose. The thickness of the same may be 20 to 30cm. The thickness of filter for the next 30 to 45m on the upstream face may be reduced to about 15 cm and beyond that, it can be omitted.

A typical layout of a spur is shown is Figure 6.

6.1.5 Cut-offs

Cut-offs as river training works are to be carefully planned and executed in meandering rivers. The cut-off is artificially induced with a pilot channel to divert the river from a curved flow which may be endangering valuable land or property or to straighten its approach to a work or for any other purpose. As the cut-off shortens the length of the river, it is likely to cause disturbance of regime upstream and downstream till readjustment is made. A pilot cut spreads out the period of readjustment and makes the process gradual. Model tests come in handy in finalising this form of river training works wherever needed.

A typical instance of a cutoff is shown in Figure 7.

6.1.6 Marginal embankments

These are earthen embankments, also known as levees, which are constructed in the flood plains of a river and run parallel to the river bank along its length. The aim of providing these embankments is to confine the river flood water within the cross section available between the embankments. The flood water of a river is thus not allowed to spill over to the flood plains, as normally would had been (Figure 8). This kind of protection against flooding has been provided for most of the rivers of India that are flood prone with low banks and have extensive flood plains in the last century. This may be apparent from the maps of any riverine area, as shown typically in Figure 9.

However, the ill effects of providing these embankments have become quite apparent now, the most serious of which is the gradual rise of the river bed level over the years due to deposition of sediments. Normally, a river in its original unrestricted shape deposits silt along with flood water not only in its riverbed, but also on its flood plains (Figure 10a). However, as soon a river is confined by marginal embankments, the subsequent deposits of sediment can only take place over the river bed, thus raising the bed elevation (Figure 10b). Instance of such phenomena has been reported for such bis rivers like the Mississippi in the USA. In India, embanking of the Mahanadi river near Cuttack or the Ganga near Patna or the Teesta near Talpaiguri have all caused the river bed level to have gone up alarmingly. As a consequence, during floods, the river water level flows alarmingly high (Figure 10c), and the residents of the nearly towns are always under the threat of flooding.

In view of the seriousness of this issue, marginal embankments are now being discouraged. The flood plains rightly belong to the river, and forceful occupation of these by artificial means like constructing embankments is harmful to the river as well as human society itself, who had engineered the constructions.

6.1.7 Riverbank protection works

This aspect of river engineering considers methods and techniques for protecting the banks of rivers from collapsing. Hence, certain structural interventions are required to be implemented, which are termed as the riverbank protection works or alternately as bank stabilization structures. Generally these are simple to construct though, the specific hydraulic and geomorphic process associated with these structures are quite complex and challenging. Hence, the type of bank protection work has to be in accordance with the conditions of the specific site – a method suitable for one location of a river may not be so far another location of the same river or at another river. For a proper appreciation of the techniques of bank stabilization, one has to have an awareness about fluvial geomorphology and channel processes, a brief account of which has been discussed in Module 2.

Nevertheless, geomorphic analyses of initial morphological response to system disturbance provides a simple qualitative method for predicting the channel response to an altered condition. Another complicating factor in assessing the cause and effect of system instability is that very rarely is the instability a result of a single factor. In a watershed where numerous alterations (dams, levees, channelization, land use changes, etc.) have occurred, the channel morphology will reflect the integration of all these factors. Unfortunately, it is extremely difficult and often impossible to sort out the precise contributions of each of these components to the system instability. The interaction of these individual factors coupled with the potential for complex response makes assessing the channel stability and recommending channel improvement features, such as bank protection, extremely difficult. There are numerous qualitative and quantitative procedures that are available. Regardless of the procedure used, the designer should always recognize the limitations of the procedure, and the inherent uncertainties with respect to predicting the behavior of complex river systems.

Local instability

Local instability is a term that refers to bank erosion that is not symptomatic of a dis- equilibrium condition in the watershed (i.e., system instability) but results from site specific factors and processes. Perhaps the most common form of local instability is bank erosion along the concave bank in a meander bend which is occurring as part of the natural meander process. Local instability does not imply that bank erosion in a channel system is occurring at only one location or that the consequences of this erosion are minimal. As discussed earlier, erosion can occur along the banks of a river in dynamic equilibrium. In these instances the local erosion problems are amenable to local protection works such as bank stabilization measures. However, local instability

can also exist in channels where severe system instability exists. In these situations the local erosion problems will probably be accelerated due to the system instability, and a more comprehensive treatment plan will be necessary. Local instability of a riverbank may be due to either streambank erosion or erosion due to meander bends. These are explained below.

Streambank erosion and failure processes

The terms streambank erosion and streambank failure are often used to describe the removal of bank material. Erosion generally refers to the hydraulic process where individual soil particles at the bank’s surface are carried away by the tractive force of the flowing water. The tractive force increases as the water velocity and depth of flow increase. Therefore, the erosive forces are generally greater at higher flows. Streambank failure differs from erosion in that a relatively large section of bank fails and slides into the channel. Streambank failure is often considered to be a geotechnical process. The important processes responsible for bank erosion are described in the following section.

Meander Bend Erosion

Depending upon the academic training of the individual, streambank erosion may be considered as either a hydraulic or a geotechnical process. However, in most instances the bank retreat is the result of the combination of both hydraulic and geotechnical processes. The material may be removed grain by grain if the banks are non-cohesive (sands and gravels), or in aggregates (large clumps) if the banks are composed of more cohesive material (silts and clays). This erosion of the bed and bank material increases the height and angle of the streambank which increases the susceptibility of the banks to mass failure under gravity. Once mass failure occurs, the bank material will come to rest along the bank toe. The failed bank material may be in the form of a completely disaggregated slough deposit or as an almost intact block, depending upon the type of bank material, the degree of root binding, and the type of failure. If the failed material is not removed by subsequent flows, then it may increase the stability of the bank by forming a buttress at the bank toe. This may be thought of as a natural form of toe protection, particularly if vegetation becomes established. However, if this material is removed by the flow, then the stability of the banks will be again reduced and the failure process may be repeated.

As noted above, erosion in meander bends is probably the most common process responsible for local bank retreat and, consequently, is the most frequent reason for initiating a bank stabilization program. A key element in stabilization of an eroding meander bend is an understanding of the location and severity of erosion in the bend, both of which will vary with stage and plan form geometry.

As streamflow moves through a bend, the velocity (and tractive force) along the outer bank increases. In some cases, the tractive force may be twice that in a straight reach just upstream or downstream of the bend. Consequently, erosion in bends is generally much greater than in straighter reaches. The tractive force is also greater in bends with short radius than those with larger ones. The severity of bank erosion also changes with stage. At low flows, the main thread of current tends to follow the concave bank

alignment. However, as flow increases, the streamlines tend to cut across the convex bar to be concentrated against the concave bank below the apex of the bend. Because of this process, meanders tend to move downstream, and the zone of maximum erosion is usually in the downstream portion of the bend level due to the flow impingement at the higher flows.

6.1.8 Erosional forces for bank failure

It is not quite easy to identify the processes responsible for the bank erosion. In this section, the primary causes of bank erosion are described briefly.

Parallel flow erosion is the detachment and removal of intact grains or aggregates of grains from the bank face by flow along the bank. Evidence includes: observation of high flow velocities close to the bank; near bank scouring of the bed; under-cutting of the toe/lower bank relative to the bank top; a fresh, ragged appearance to the bank face; absence of surficial bank vegetation.

Impinging flow erosion is detachment and removal of grains or aggregates of grains by flow attacking the bank at a steep angle to the long-stream direction. Impinging flow occurs in braided channels where braid-bars direct the flow strongly against the bank, in tight meander bends where the radius of curvature of the outer bank is less than that of the channel centerline, and at other locations where an in-stream obstruction deflects and disrupts the orderly flow of water. Evidence includes: observation of high flow velocities approaching the bank at an acute angle to the bank; near-bank scouring of the bed; under-cutting of the toe/lower bank relative to the bank top; a fresh, ragged appearance to the bank face; absence of surficial bank vegetation.

Piping is caused by groundwater seeping out of the bank face. Grains are detached and entrained by the seepage flow (also termed sapping) and may be transported away from the bank face by surface runoff generated by the seepage, if there is sufficient volume of flow. Piping is especially likely in high banks backed by the valley side, a terrace, or some other high ground. In these locations the high head of water can cause large seepage pressures to occur. Evidence includes: Pronounced seep lines, especially along sand layers or lenses in the bank; pipe shaped cavities in the bank; notches in the bank associated with seepage zones and layers; run-out deposits of eroded material on the lower bank.

Freeze/thaw is caused by sub-zero temperatures which promote freezing of the bank material. Ice wedging cleaves apart blocks of soil. Needle-ice formation loosens and detaches grains and cleaves apart blocks of soil. Needle-ice formation loosens and detaches grains and crumbs at the bank face. Freeze/thaw activity seriously weakens the bank and increases its erodibility. Evidence includes: periods of below freezing temperatures in the river valley; a loose, crumbling surface layer of soil on the bank;

loosened crumbs accumulated at the foot of the bank after a frost event; jumbled blocks of loosened bank material.

Sheet erosion is the removal of a surface layer of soil by non-channelized surface run- off. It results from surface water draining over the bank edge, especially where the riparian and bank vegetation has been destroyed by encroachment of human activities. Evidence includes: Surface water drainage down the bank; lack of vegetation cover, fresh appearance to the soil surface; eroded debris accumulated on the lower bank/toe area.

Rilling and gullying occurs when there is sufficient uncontrolled surface run-off over the bank to utilize channelized erosion. This is especially likely where flood plain drainage has been concentrated (often unintentionally) by human activity. Typical locations might be near buildings and parking lots, stock access points and along stream-side paths. Evidence includes: a corrugated appearance to the bank surface due to closely spaced rills; larger gullied channels incised into the bank face; headward erosion of small tributary gullies into the flood plain surface; and eroded material accumulated on the lower bank/toe in the form of alluvial cones and fans.

Wind waves cause velocity and shear stresses to increase and generate rapid water level fluctuations at the bank. They cause measurable erosion only on large rivers with long fetches which allow the build up of significant waves. Evidence includes: a large channel width or a long, straight channel with an acute angle between eroding bank and longstream direction; a wave-cut notch just above normal low water plane; a wave-cut platform of run-up beach around normal low-water plane.

Vessel forces can generate bank erosion in a number of ways. The most obvious way is through the generation of surface waves at the bow and stern which run up against the bank in a similar fashion to wind waves. In the case of large vessels and/or high speeds these waves may be very damaging. If the size of the vessel is large compared to the dimensions of the channel hydrodynamic effects produce surges and drawdown in the flow. These rapid changes in water level can loosen and erode material on the banks through generating rapid pore water pressure fluctuations. If the vessels are relatively close to the bank, propeller wash can erode material and re-suspend sediments on the bank below the water surface. Finally, mooring vessels along the bank may involve mechanical damage by the hull. Evidence includes: use of river for navigation; large vessels moving close to the bank; high speeds and observation of significant vessel-induced waves and surges; a wave-cut notch just above the normal low-water plane; a wave-cut platform or “spending” beach around normal low-water plane.

Retreat of river bank often involves geotechnical bank failures as well as direct erosion by the flow. Such failures are often termed as “bank sloughing” or “caving”. Examples of different modes of geotechnical stream bank failure are explained in the next section.

6.1.9 Different modes of bank failure

This section summarizes the different ways by which a river bank collapses by classifying them using geotechnical terminologies.

Soil/rock fall occurs only on a steep bank where grains, grain assemblages or blocks fall into the channel. Such failures are found on steep, eroding banks of low operational cohesion. Soil and rock falls often occur when a stream undercuts the toe of a sand, gravel or deeply weathered rock bank. Evidence includes: very steep banks; debris falling into the channel; failure masses broken into small blocks; no rotation or sliding failures.

Shallow slide is a shallow seated failure along a plane somewhat parallel to the ground surface. Such failure are common on bank of low cohesion. Shallow slides often occur as secondary failures are common on banks of low cohesion. Shallow slides often occur as secondary failures following rotational slips and/or slab failures. Evidence includes: weakly cohesive bank materials; thin slide layers relative to their area; planar failure surface; no rotation or toppling of failure mass.

Rotational slip is the most widely recognised type of mass failure mode. A deep seated failure along a curved surface results in bank-tilting of the failed mass toward the bank. Such failures are common in high, strongly cohesive banks with slope angles below about 600. Evidence includes: banks formed in cohesive soils; high, but not especially steep, banks; deep seated, curved failures scars; back-tilting of the top of failure blocks towards intact bank; arcuate shape to intact bank line behind failure mass.

Slab-type block failure is sliding and forward toppling of a deep seated mass into the channel. Often there are deep tension cracks in the bank behind the failure block. Slab failures occur in cohesive banks with steep bank angles greater than about 600. Such banks are often the result of toe scour and under-cutting of the bank by parallel and impinging flow erosion.

Evidence includes: cohesive bank materials; steep bank angles; deep seated failure surface with a planar lower slope and nearly vertical upper slope; deep tension cracks behind the bank-line; forward tilting of failure mass into channel; planner shape to intact bank-line behind failure mass.

Cantilever failure is the collapse of an overhanging block into the channel. Such failures occur in composite and layered banks where a strongly cohesive layer is underlain by a less resistance one. Under-mining by flow erosion, piping, wave action and/or pop-out failure leaves an overhang which collapses by a beam, shear or tensile failure. Often the upper layer is held together by plant roots. Evidence includes: composite or layered bank stratigraphy; cohesive layer underlain by less resistant layer; under-mining; overhanging bank blocks; failed blocks on the lower bank and at the bank toe.

Pop-out failure results from saturation and strong seepage in the lower half of a steep, cohesive bank. A slab of material in the lower half of the steep bank face falls out, leaving an alcove-shaped cavity. The over-hanging roof of the alcove subsequently collapses as a cantilever failure. Evidence includes: cohesive bank materials; steep bank face with seepage area low in the bank; alcove shaped cavities in bank face.

Piping failure is the collapse of part of the bank due to high groundwater seepage pressures and rates of flow. Such are an extension of the piping erosion process described previously, to the point that there is complete loss of strength in the seepage layer. Sections of bank disintegrate and are entrained by the seepage flow (sapping). They may be transported away from the bank face by surface run-off generated by the seepage, if there is sufficient volume of flow. Evidence includes: pronounced seep lines, especially along sand layers or lenses in the bank; pipe shaped cavities in the bank; notches in the bank associated with seepage zones; run-out deposits of eroded material on the lower bank or beach. Note that the effects of piping failure can easily be mistaken for those of wave vessel force erosion.

Dry granular flow describes the flow-type failure of a dry, granular bank material. When a noncohesive bank at close to the angle of repose is undercut, increasing the local bank angle above the friction angle. A carpet of grains rolls, slides and bounces down the bank in a layer up to a few grains thick. Evidence includes: noncohesive bank materials; bank angle close to the angle of repose; undercutting; toe accumulation of loose grains in cones and fans.

Wet earth flow failure is the loss of strength of a section of bank due to saturation. Such failures occur when water-logging of the bank increases its weight and decreases its strength to the point that the soil flows as a highly viscous liquid. This may occur following heavy and prolonged precipitation, snow-melt or rapid drawdown in the channel. Evidence includes: sections of bank which have failed at very low angles; areas of formerly flowing soil that have been preserved when the soil dried out; basal accumulation of soil showing delta-like patterns and structures.

6.1.10 Techniques for bank stabilization

There could be two broad ways of stabilizing banks – firstly the direct methods of protecting the slope, and secondly the indirect way by providing structures that extend into the stream channels and redirect the flow so that hydraulic forces at the channel boundary are reduced to a non – erosive level.

Amongst the direct methods available for bank stabilization, the following broad categories are as follows:

• Self-adjusting armour made of stone or other materials

• Rigid armour

• Flexible mattress

The advantages of this type protection are that armoring the surface of the bank is a proven approach which can be precisely designed for a given situation, and which provides immediate and effective protection against erosion. Also, existing or potential problems from erosion by overbank drainage can be effectively addressed integrally with the design of the streambank armor work. Disadvantages for these types of bank protection include preparation of the bank slope is usually required, either for geotechnical stability or to provide a smooth surface for proper placement of the armor. This may result in high cost, environmental damage, and disturbance to adjacent structures. The extent of earthwork associated with an armor revetment will be especially significant if the existing channel alignment is to be modified either by excavation or by placing fill material in the channel. The following sections describe the three types of bank protection works.

As for the indirect methods for bank stabilization, these may be classified into the following categories.

• Dikes – Permeable or Impermeable

• Retards – Permeable or Impermeable

• Other flow deflectors, like Bendway weirs, Iowa vanes, etc.

The advantages of this type of protection are that little or no bank preparation is involved. This reduces costs of local environmental impacts, and simplifies land aquisition. However, the main disadvantage is that these are not very effective where geotechnical bank instability or erosion from overbank drainage are the main causes of bank erosion. Further the construction of these are not very effective where geotechnical bank instability or erosion from overbank drainage are the main causes of bank erosion. Further, the construction of these structures induce significant changes in flow alignment, channel geometry, roughness and other hydraulic factors, which have to be carefully checked to find out any adverse implication of the river’s geomorphology. Some types of indirect protection may also pose safety hazard if the stream is used for recreation or navigation. Lastly, since indirect methods require structures to be constructed deep into the stream channel, their construction may become practically difficult, especially during high flows.

Details about these indirect methods of bank protection are not presented in this lesson, but may be obtained from references such as “The WES Stream Investigation and Streambank Stabilization Hand book”, published by the U.S. Army Engineer Waterways Experiment Station (WES) in 1997.

6.1.11 Self-adjusting armour of stone or other material

Stone armour can be placed in four general configurations, the most common being a “riprap blanket”. Other forms, known as “trenchfill”, “longitudinal stone toe,” and “windrow” (referred to in some regions as “falling apron”), canbe very useful in certain situations.

A stone armor usually consists of “graded” stone, which is a mixture of a wide range of stone sizes; the largest sizes resist hydraulic forces, and the smaller sizes add interlocking support and prevent loss of bank material through gaps between larger stones. Hand-placed stone in a smaller range of sizes is occasionally used. The various types of stone armours are discussed below:

Riprap Blanket

Riprap (Figure 11) should be blocky in shape rather than elongated, as more nearly cubical stones “nest” together best and are more resistant to movement. The stone should have sharp, clean edges at the intersections of relatively flat faces. Cobbles with rounded edges are less resistant to movement, although the drag force on a rounded stone is less than on sharp-edged cubical stones. As graded cobble interlock is less than that of equal-sized angular stones, the cobble mass is more likely to be eroded by channel flow. If used, the cobbles should be placed on flatter side slopes than angular stone and should be about 25 percent larger in diameter.

The bed material and local scour characteristics determine the design of toe protection, which is essential for riprap revetment stability. The bank material and ground water conditions affect the need for filters between the riprap and underlying material. Construction quality control of both stone production and riprap placement is essential

for successful bank protection. Riprap protection for flood-control channels and appurtenant structures should be designed so that any flood that could reasonably be expected to occur during the service life of the channel or structure would not cause damage exceeding nominal maintenance. While the procedures presented herein yield definite stone sizes, results should be used for guidance purposes and revised if appropriate, based on experience with specific project conditions.

Trenchfill

A trenchfill revetment, shown in Figure 12, is simply a standard stone armor revetment with a massive stone toe. It is normally constructed in an excavated trench behind the river bank, in anticipation that the river will complete the work by eroding to the revetment, causing the stone toe to launch down and armor the subsequent bank slope.

Material other than stone, such as broken soil-cement, has been used successfully and may be less costly than stone, but careful design of the soil/cement mixture, and careful monitoring of the material mixing, breaking, and placing operation is required.

Windrow

A windrow revetment (Figure 13) is simply an extreme variation of a trenchfill revetment. A window revetment consists of rock placed on the floodplain surface landward from the existing bankline at a pre-determined location, beyond which additional erosion is to be prevented.

Longitudinal stone toe

Longitudinal stone toe (Figure 14) is another form of a window revetment, with the stone placed along the existing streambed rather than on top bank. The longitudinal stone toe is placed with the crown well below top bank, and either against the eroding bankline or a distance riverward of the high bank. Typical crown elevations may vary but are commonly between 1/3 and 2/3 of the height to top bank.

The success of longitudinal stone toe protection is based on the premise that as the toe of the bank is stabilized, upper bank failure will continue until a stable slope is attained and the bank is stabilized. This stability is usually assisted by the establishment of vegetation along the bank.

Concrete blocks

These are armour revetment for bank stabilization consisting of loose concrete blocks. Concrete blocks fastened together forms a kind of flexible mattress that is discussed in Section 6.1.13.

A wide variety of block shapes and placement techniques can be used. Some have evolved from engineering analyses, some from observation and empiricism, and some from improvisation using readily available materials. Blocks designed specifically for bank armor are commercially available. Forms for casting concrete blocks locally are often available from distributors, and may be an economical alternative to purchasing and transporting precast blocks.

A fabric or granular underlayment (“filter”) is often required for riverbank protection by concrete blocks. Successful performance of the underlayment is more critical than with a riprap armour. In areas of high turbulence or waves, displacement of one block can lead to successive displacement of adjacent blocks. If blocks are cast on-site, delays from inclement weather may be a problem. At sites that are subject to theft or vandalism, blocks of an attractive size and shape may suffer serious attrition.

Sacks

Sacks as an armor material can be considered to be artificial “rocks” of uniform size and shape. The sacks may be made of paper, burlap, or a synthetic material. The fill material may be soil or aggregate of various types, with or without cement. Sacks can be placed on a steeper slope than stone. Materials are often available locally. The hydraulic roughness is low, and they form a walkable surface. The “cobblestone” effect may be more aesthetic than some other materials. As far concrete blocks, a fabric or granular filter is usually required.

Soil-cement blocks

Soil is mixed well with sufficient cement to provide a durable bond between soil particles. The resulting monolith is broken into blocks of various sizes, which are used to armor the bank. Besides the general characteristics of adjustability to bank irregularities and self-healing properties, soil-cement blocks allow the utilization of locally available materials. However, soil-cement blocks have a lower specific weight than riprap, and obtaining acceptable gradation and durability are highly dependent on closely controlled construction operations. Construction operations are adversely affected by wet or cold weather.

6.1.12 Rigid armour

Rigid armour is an erosion-resistant material which has little or no flexibility to conform to bank irregularities occurring after construction. Typically, the armour is placed directly on the bank slope in a fluid or chemically reactive state, then hardens.

The most common rigid armours are:

• Asphalt

• Concrete

• Grouted riprap (or other grouted armour material), and

• Soil-cement

The main advantages for a rigid armour are: The most common rigid armours will withstand high velocities, have low hydraulic roughness, and prevent infiltration of water into the channel bank. They are practically immune to vandalism, damage from debris, corrosion, and many other destructive agents. The most common rigid armours are easily traversed by pedestrians.

However, a rigid armour requires careful design and quality control during construction, and unfavourable weather conditions can cause construction delays. Provision for draining groundwater and preventing the builtup of excess positive pore water pressures, in the form of a filter or subsurface drains, must usually be provided for impermeable armours, which may significantly increase the cost of the project. Most rigid armours are difficult or impossible to construct underwater, although this difficulty can be alleviated for concrete by using one of the commercially available fabric mattresses. Asphalt has been placed underwater in some mattresses. Rigid armour, being inflexible, is susceptible to breaching if the bank material subsides or heaves. Increased wave runup on a smooth rigid armour may be a concern for some projects.

Typical applications of rigid armour in the form of concrete, asphalt, or grouted riprap is often considered for use in situations where high velocities or extreme turbulence make adjustable armour ineffective or very expensive. Typical uses are in conjunction with hydraulic structures or in artificial channels on steep slopes. Rigid armour may be the preferred alternative in flood control or drainage channels where low boundary roughness is mandatory, or in water supply channels where prevention of water loss due to infiltration into the bank is important. It is suitable for bank slopes which must be easily traversed by pedestrians or recreational users, if the slope is not too steep for safety. Rigid armour is sometimes the least costly alternative, typically where adjustable armour is not available locally, especially if a geotechnical analysis of the bank material indicates that elaborate subsurface drainage work is not necessary.

The important types of rigid armour are discussed in the following paragraphs.

Asphalt

Asphalt mixes with a high sand content are sometimes used to retain some permeability to relieve hydrostatic pressure. However, these mixes have been reported to become more brittle and less permeable upon long exposure to the elements, and weathering may result in a slow loss of thickness.

Concrete

On slopes above water, concrete can be placed in the conventional manner with forms, or can be pumped into fabric mattresses which serve as forms for a fine aggregate concrete. Prefabricated slabs would assume some of the characteristics of concrete block armour.

Grouted armour

Grouting of an armour layer with asphalt or concrete enables the armour to withstand higher flow velocities, provides a smooth surface for pedestrian or vehicle access, and reduces the hydraulic roughness of the armour. Grouting is also sometimes used with gabion armours or structures to increase the resistance of the gabions to corrosion and abrasion.

Soil-cement

Soil-cement will withstand relatively high velocities and is usually less expensive than concrete, asphalt, and grouted riprap. It is more durable than chemical stabilization, clay, and certainly ice, but usually somewhat less durable than concrete, asphalt, and grouted riprap, assuming that sound design and construction procedures are followed for all.

6.1.13 Flexible mattress

The basic concept of a flexible mattress is that material or objects which cannot resist erosive forces separately can be fastened together or placed in a flexible container to provide adequate resistance to erosive forces, while partially retaining the desirable characteristics of adjustable armour, especially that of flexibility.

The most common flexible mattress materials are:

• Concrete blocks;

• Fabric; and

• Gabions.

The advantages of this type of riverbank protection work includes its flexibility to adjust to scour or settlement and still remain in contact with the bed and bank is the most obvious shared trait. Most mattress materials which are sold under trade names share another advantage they are available in various configurations, thus can be applied to a variety of situations. Flexible mattresses can be placed underwater with a relatively high degree of confidence. If properly anchored to a geotechnically stable bank, they can be placed on steep slopes. They can be walked upon easily, thus are suitable for slopes used by pedestrians.

However, it must be kept in mind that mattress components are subject to deterioration from the elements and vandalism. The damage is often within acceptable limits through,

and, since the various types are affected differently, identification of the hazards enables the designer to select an appropriate mattress for a given application. The construction of some types of mattress is labour intensive, and may require skills not commonly available. However, the labour intensive aspect may not be a disadvantage in all cases, and may be an advantage in some cases.

Typical applications of flexible mattresses are: This compromise between adjustable armour and rigid armour is most attractive when economical materials can be used for the mattress. In fact, the origin of some variations can be traced directly to creative use of local materials where no protective material of local origin was adequate to withstand the erosive forces in a given application, and where the most suitable method was the one which required the least amount of costly imported material, a requirement which is often met by a flexible mattress.

Some of the common forms of flexible mattresses are explained below:

Concrete block mattress

Mattresses provide a higher degree of safety from progressive failure of the armour due to displacement of individual blocks from hydraulic or geotechnical forces or vandalism. Placing of mattresses is more mechanized and less labour intensive than placing individual blocks. Precast concrete blocks can be formed into a flexible mattress in several ways: by fastening them to engineering fabric, by fastening them together with cable or synthetic rope, or by forming them in ingenious shapes which are then interlocked. All of these varieties are commercially available.

Fabric Mattress

Fabric mattresses made of synthetic material and filled with concrete grout, other cohesive mixtures, or sand are available from various manufactures. Tubular-shaped bags are also available; these can be filled and placed either parallel to the streambank as a bulkhead or perpendicular to the streambank as a dike, or can be used to fill scour holes or undermined slopes. A fabric mattress is relatively easy to place, and fill material is often available locally. Some designs have a low hydraulic roughness.

Gabion Mattress

A gabion mattress consists of a mesh container filled with cobbles or quarried stone. Several firms market the containers and furnish technical assistance. Spacialized equipment or accessories used on large jobs for efficiency, or on jobs requiring underwater placement.

A form of gabion which is a hybrid between flexible mattress and adjustable armour is the “sack” or “sausage,” which can be filled faster than mattress or box shapes, making it suitable for use in emergency situations. However, it makes less efficient use of material, and is less common than traditional mattress or boxes.

Vegetation (Fascine) Mattress

Wooden mattress is one of the oldest techniques of bank stabilization, even though it is seldom used now in developed regions. The mats may be made of poles, brush, or

lumber. The material can be fastened together by weaving, binding, cabling, clamping, or spiking. The mattresses are sunk by ballasting with stone or other heavy materials. Some types of mat may be so buoyant that the ballast is a significant component of the protection, as well as a large part of the cost.

On navigable rivers during periods when current speed is slow enough that the mats can be safely maneuvered in tow, mats with sufficient buoyancy can be safely maneuvered in tow, mats with sufficient buoyancy can be assembled near the materials supply point or near a source of labour, then towed to the project site.

At least one marine construction firm has adapted modern technology to the construction of wooden mattress, while still retaining traditional skills for use where appropriate. They have also extended new technology to the point of developing synthetic materials for use in mattresses, in order to overcome some of the inherent problems of wood.

The main advantage of this type of bank protection is that its main raw material, that is, wood is usually available locally, and is a renewable resource. If inexpensive labour is available, a wooden mattress may be the least cost alternative. Wood is relatively durable when permanently submerged in freshwater. However, near-site availability of material is usually required for wooden mat to be competitive with other methods. Assembling and placing the mattresses are labour-intensive operations. Design and construction is surprisingly complex, requiring skills which have become rarer as other methods have become have more popular. At some instances, bamboo mattresses have proved very effective as fascine mattress.